In the dynamic world of aerospace engineering, the quest for lightweight yet robust materials has reached unprecedented levels. Enter composite materials – a transformative innovation reshaping the landscape of aircraft part design, construction, and composite manufacturing. Composites, comprising various layers or fibres bonded together, offer a unique blend of strength, durability, and flexibility, making them indispensable in modern aerospace applications.

Advantages of Composite Materials in Aerospace

Composite materials confer several advantages in aerospace applications. Chief among these is their reduced weight compared to conventional materials like metal alloys. This weight reduction translates into enhanced fuel efficiency and lowered airline operational costs. The lightweight nature of composites allows for increased payload capacity or extended flight ranges.

Another key advantage is the exceptional strength-to-weight ratio of composite materials. This property makes them ideal for critical aircraft structures such as wings and fuselages, where high strength and stiffness are paramount. By leveraging composite materials, engineers can fashion lighter yet stronger structures capable of withstanding the extreme forces encountered during flight.

Composite materials also exhibit superior resistance to corrosion and fatigue compared to traditional materials. Unlike metal alloys, which are susceptible to corrosion in harsh environments, composites remain unaffected by such conditions, resulting in prolonged longevity and reduced maintenance expenses. Additionally, composites demonstrate enhanced fatigue resistance, essential for preserving the structural integrity of aircraft components over their operational lifespan.

Types of Composite Materials in Aerospace

Several composite materials are used in aerospace, each endowed with unique properties and characteristics. These differences are due to the constituent materials and the specific composite manufacturing process. These constituent materials, such as fibres and resin, are combined to create a new material that exhibits characteristics superior to those of its components.

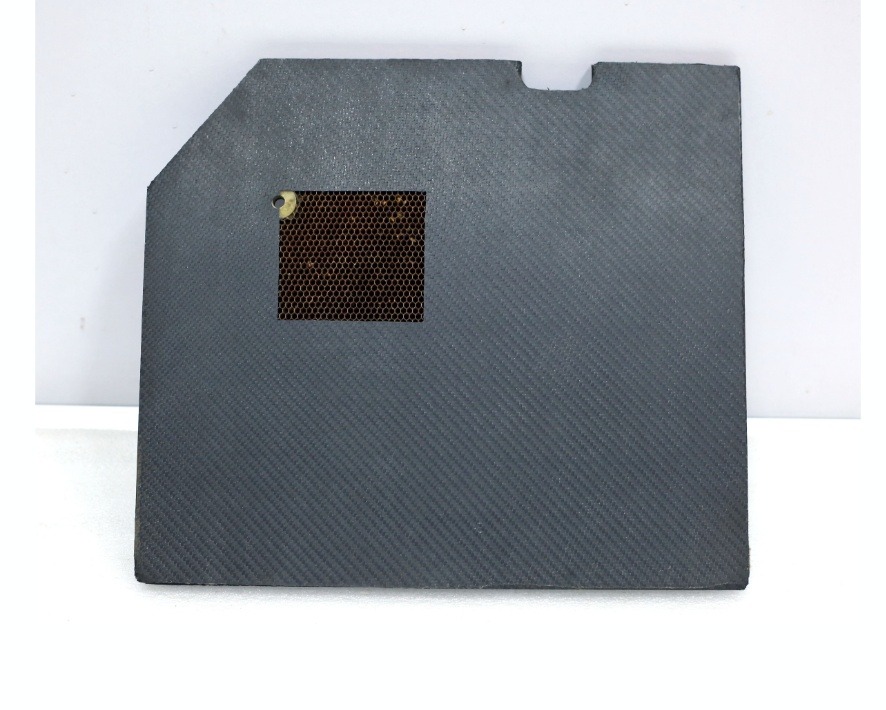

Carbon-fibre reinforced polymers (CFRP) represent one prevalent type, featuring carbon fibres embedded in a polymer matrix. CFRP offers exceptional strength and stiffness, rendering it suitable for demanding aircraft structures and components.

Fibreglass constitutes another common composite material comprising glass fibres within a polymer matrix. Renowned for their excellent electrical insulation properties, fibreglass composites find utility in radomes and other electrical components. Compared to other composite materials, their affordability makes them a favoured choice for non-critical parts.

Additional composite materials include aramid fibres like Kevlar, prized for their exceptional impact resistance, and ceramic matrix composites (CMC), renowned for their high-temperature resistance and ideal for engine components exposed to extreme heat.

Applications of Composite Materials in Aircraft Structures

Composite materials find extensive application in aircraft structures, heralding a departure from traditional metal alloy structures. Unlike their metal counterparts, composites afford greater design flexibility, enabling the creation of intricate shapes. This flexibility fuels innovation in aircraft design, optimising performance and aerodynamics. For instance, composites in wing design have spurred the development of fuel-efficient configurations such as blended wing-body designs.

Composites offer enhanced resistance to fatigue and corrosion, prolonging service life and reducing maintenance demands. Additionally, composite structures can integrate functionalities like built-in sensors for structural health monitoring, augmenting safety and efficiency.

Composite Materials in Engine Components

Composite materials feature prominently in various engine components where high-temperature resistance and lightweight properties are indispensable. Fan blades and fan cases crafted from composites offer significant weight savings, translating into improved fuel efficiency and reduced emissions. Composite fan containment cases ensure passenger safety in fan blade failure, owing to their strength and impact resistance.

Composite materials find application in engine nacelles, offering weight reduction and superior resistance to heat and corrosion, thereby enhancing aerodynamic efficiency.

Composite Materials in Interior and Cabin Parts

Composite materials play a pivotal role in crafting aircraft’s interior and cabin parts. Overhead bins constructed from composites offer increased storage capacity while ensuring passenger safety owing to their lightweight yet robust nature. Composites also excel in interior panels, providing superior acoustic insulation and resistance to fire and smoke, enhancing passenger comfort and safety. Lavatory components, galleys, and seating structures benefit from composites, eventually contributing to weight reduction, durability, and an improved passenger experience.

Challenges and Future Trends

Despite their myriad benefits, composite materials pose challenges such as high manufacturing costs and susceptibility to damage from impact or environmental factors. Ongoing research endeavours aim to address these challenges and pave the way for future innovations.

Future trends in composite materials for aerospace encompass self-healing composites, bio-inspired materials, and advancements in nanotechnology. These innovations promise to enhance the performance and durability of composite materials in aerospace applications further, propelling the industry towards greater heights.

Conclusion

Composite materials represent a paradigm shift in aerospace engineering, offering various advantages ranging from weight reduction to enhanced durability and design flexibility. Despite challenges, ongoing research and development efforts by aircraft parts manufacturing companies underscore the immense potential of composite materials in revolutionising aerospace applications. As technology continues to evolve, the future of composite materials in aerospace appears promising, indicating a new era of innovation and advancement in the field.